My approach to building the prototype.

Time to get the soldering iron out

I like to prototype anything I work on, it helps to remove most of the unknowns and solidify ideas. I intent to get my PCBs made from one of those cheap board manufacturers, the only catch is they take many weeks to deliver (for free) so a prototype should reduce the number of board spins and allow me to proceed with writing the firmware.

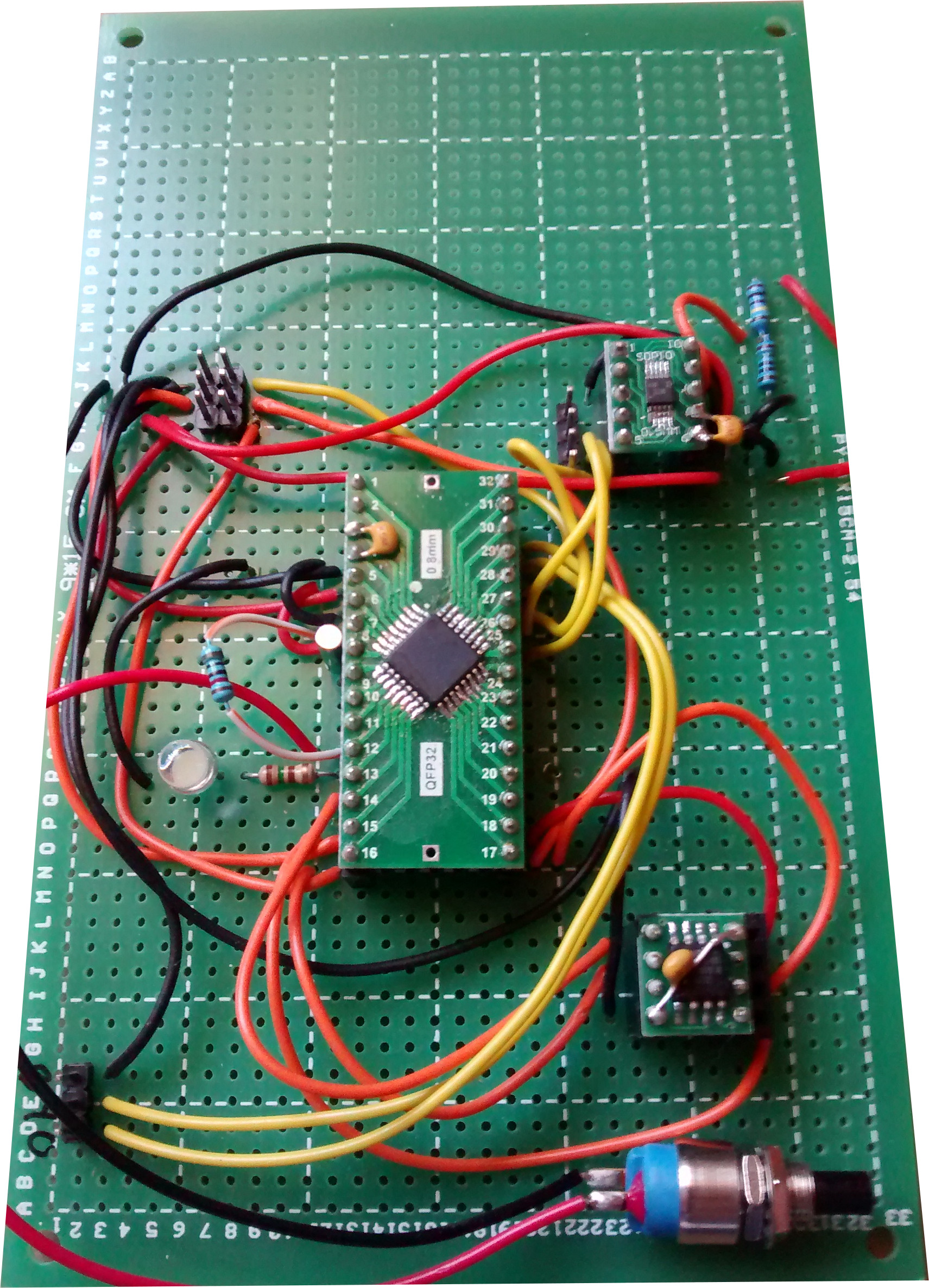

I find prototyping with through hole packages easiest, but many device only come in surface mount packages these days so I have used adapter/converter boards that you can see below. I have put decoupling capacitors close as possible to parts they are decoupling and it doesn’t seem to cause any problems.

The 6-pin header in the top left of the picture is being used to program and power the circuit with a AVR-ISP-MK2 programmer.

The wiring is a bit of a mess, but at the speed the signals are going (low), the added capacitance and inductance introduced will not be a problem.

This prototype was good enough to prove the design and write most of the firmware.